Cuba III – Tobacco in Viñales

The valley produces 70% of Cuba’s prime tobacco. Visiting the valley is like a step back in time. To avoid damage to delicate tobacco plants, animals are used to plough fields while leaves are carefully cut by hand. Beyond its importance for tobacco production, the region has garnered international attention for its scenic landscape.

Life in the valley has seen little change over the last two hundred years. Along with tobacco, the valleys farmers grow taro, banana, and sugar cane or are involved in activities such as forestry or cattle breeding. Horses remain an important mode of transportation for residents,many of whom live in traditional houses called Bohios. Constructed from wood, bohios are topped with a roof called a Yagua, made from royal palm leaves. As a result of government policies, the vast majority of Vegas (tobacco farms) are small. Farmers operating vegas that are 67 hectares or smaller are members of the National Association of Small Farmers (NASF), making them eligible for interest-free government loans. As a group, NASF members produce about 85% of tobacco grown in Cuba. By law, tobacco farmers are subject to quotas with 90% of their out-put purchased by the government and the remaining 10% reserved for personal use, much of it rolled into cigars sold to visiting tourists.

Following the harvest, leaves are taken to tobacco houses called secaderos for drying. The barns are constructed using wood and featuring an A-frame roof covered with palm leaves ,secaderos are built to ensure good air circulation.This drying is called “curing the tobacco”. During this time, the leaf color changes as well, from green, to yellow to orange and ultimately to brown. Once the leaves are brown and the edges begin to curl slightly, the tobacco has completed the air curing process. After the curing process is completed, tobacco leaves are taken down from the shed, packed and shipped to the appropriate location for fermentation, which is customized according to the type of leaf.

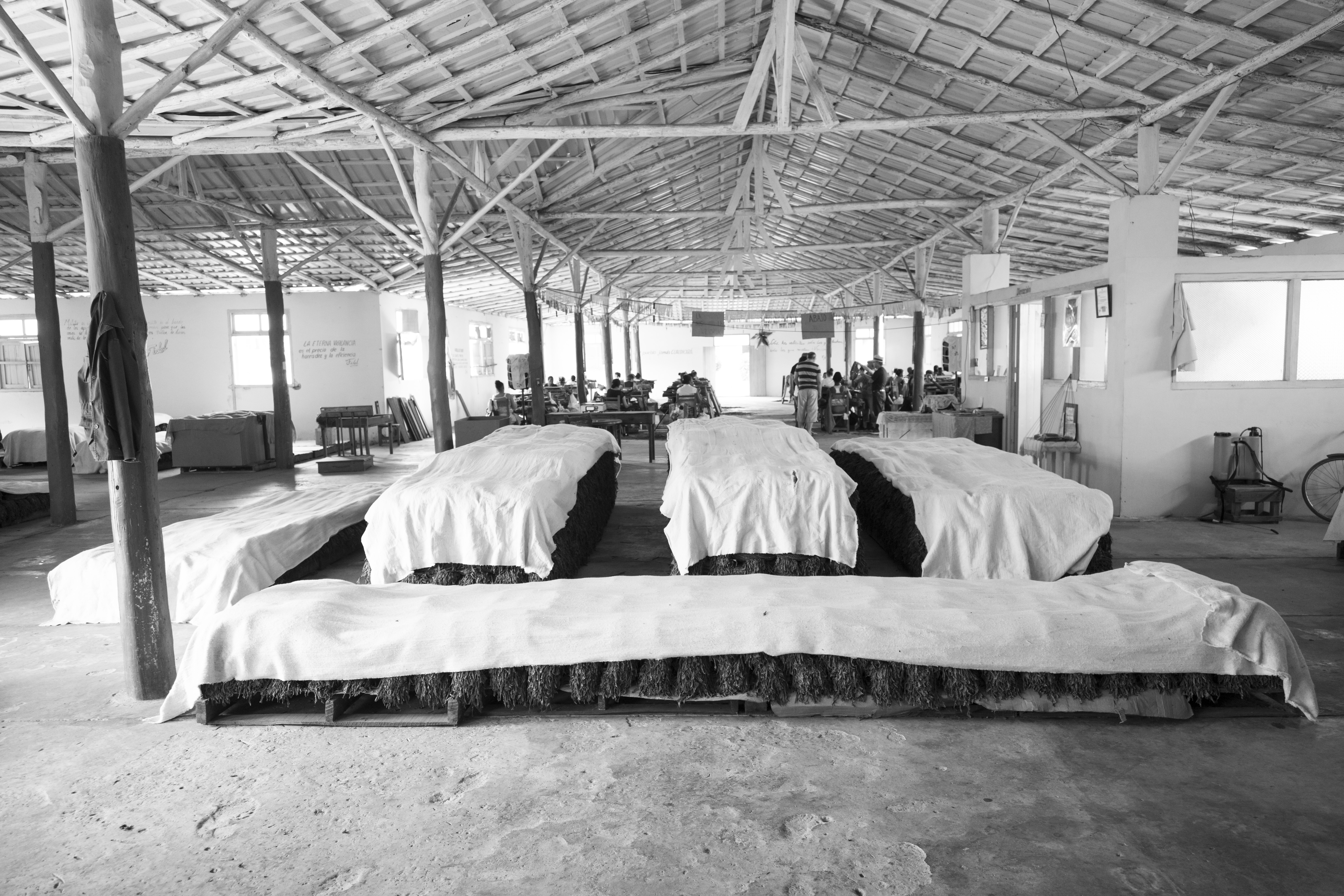

After cleaning the leaves the incoming bundles fermentation starts. Fermentation is a natural process, during which the leaf continues to ripen and the nicotine content diminishes.In addition, leaf characteristics such as the aroma, flavor and color are further developed during this process, according to pre-determined standards that is supervised as the tobacco ferments. During fermentation, the leaves are piled into what is called a bulk which is essentially stacks of cured tobacco covered in burlap to retain moisture. A bulk contains anywhere from 4,000 to 5,000 pounds of tobacco, depending on its type. The combination of the remaining water inside the leaf and the weight of the tobacco generates a natural heat which ripens the tobacco.

After cleaning the leaves the incoming bundles fermentation starts. Fermentation is a natural process, during which the leaf continues to ripen and the nicotine content diminishes.In addition, leaf characteristics such as the aroma, flavor and color are further developed during this process, according to pre-determined standards that is supervised as the tobacco ferments. During fermentation, the leaves are piled into what is called a bulk which is essentially stacks of cured tobacco covered in burlap to retain moisture. A bulk contains anywhere from 4,000 to 5,000 pounds of tobacco, depending on its type. The combination of the remaining water inside the leaf and the weight of the tobacco generates a natural heat which ripens the tobacco.

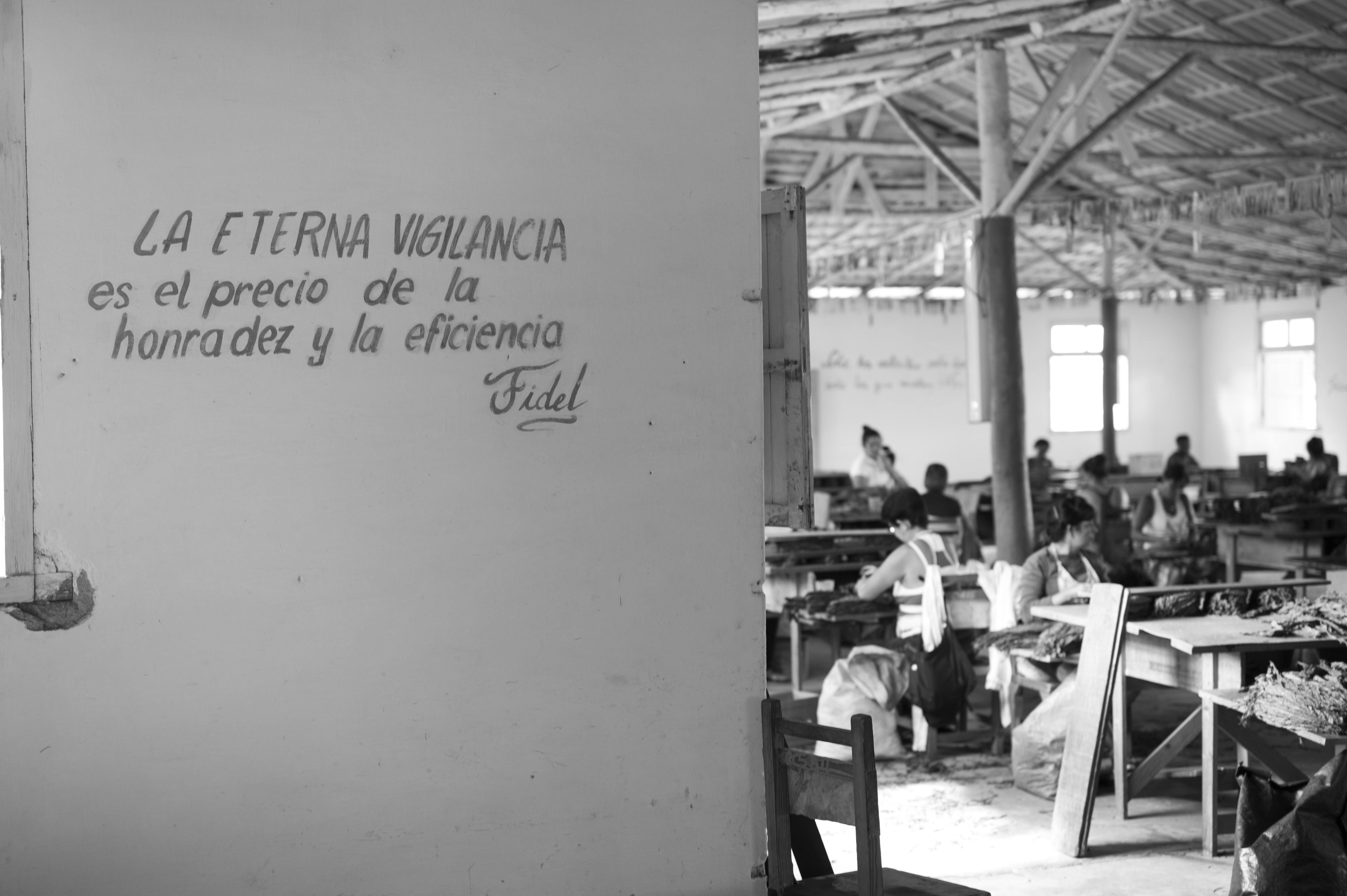

The place I visited was a “stripping house” (despalillo). The workers are called despalilladoras. The central vein of the tobacco is removed completely This portion of the leaf stem and veins contains most of the nicotine content.The leaf must be very elastic in order to remove the mid-stem, or else it will be damaged. After the stem is removed, tobacco goes to selecting. Leaf selection is a work of art, performed by very skilled artisans who are trained to have a keen eye. They must be able to sort each and every leaf based on the requirements of each cigar brand, and also by size, texture, color, color uniformity, vein color and appearance, position of secondary veins and whether the leaf is a “right” or “left.”

The place I visited was a “stripping house” (despalillo). The workers are called despalilladoras. The central vein of the tobacco is removed completely This portion of the leaf stem and veins contains most of the nicotine content.The leaf must be very elastic in order to remove the mid-stem, or else it will be damaged. After the stem is removed, tobacco goes to selecting. Leaf selection is a work of art, performed by very skilled artisans who are trained to have a keen eye. They must be able to sort each and every leaf based on the requirements of each cigar brand, and also by size, texture, color, color uniformity, vein color and appearance, position of secondary veins and whether the leaf is a “right” or “left.”

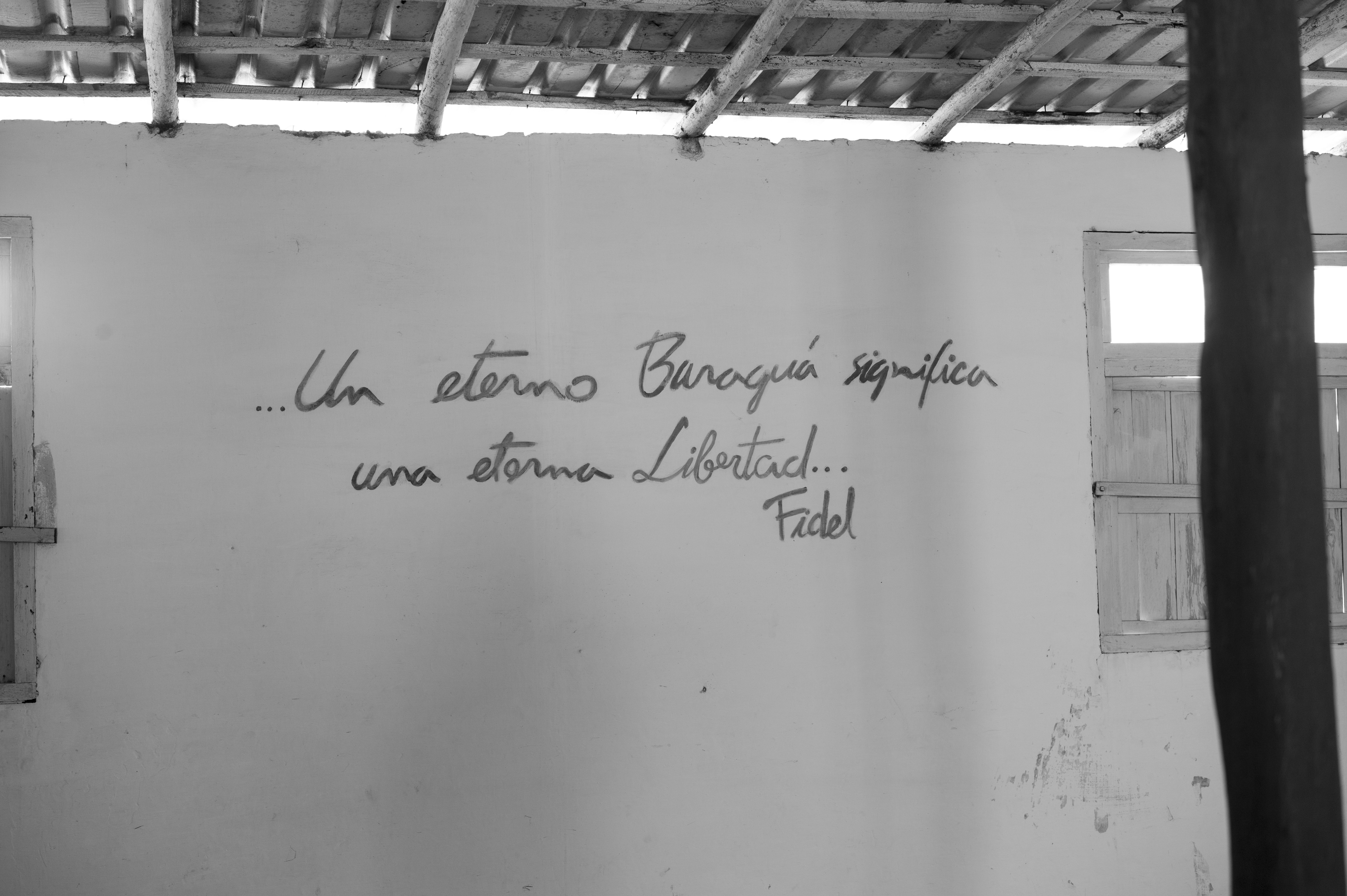

Being a state company this factory of course had encouraging writings of Fidel Castro on it’s wall.

Being a state company this factory of course had encouraging writings of Fidel Castro on it’s wall.

In this factory workes were only women, who did not seem to be stressed. They took their brakes, covering the leaves so they would keep the moisture. And one had a sense of humor…

In this factory workes were only women, who did not seem to be stressed. They took their brakes, covering the leaves so they would keep the moisture. And one had a sense of humor…

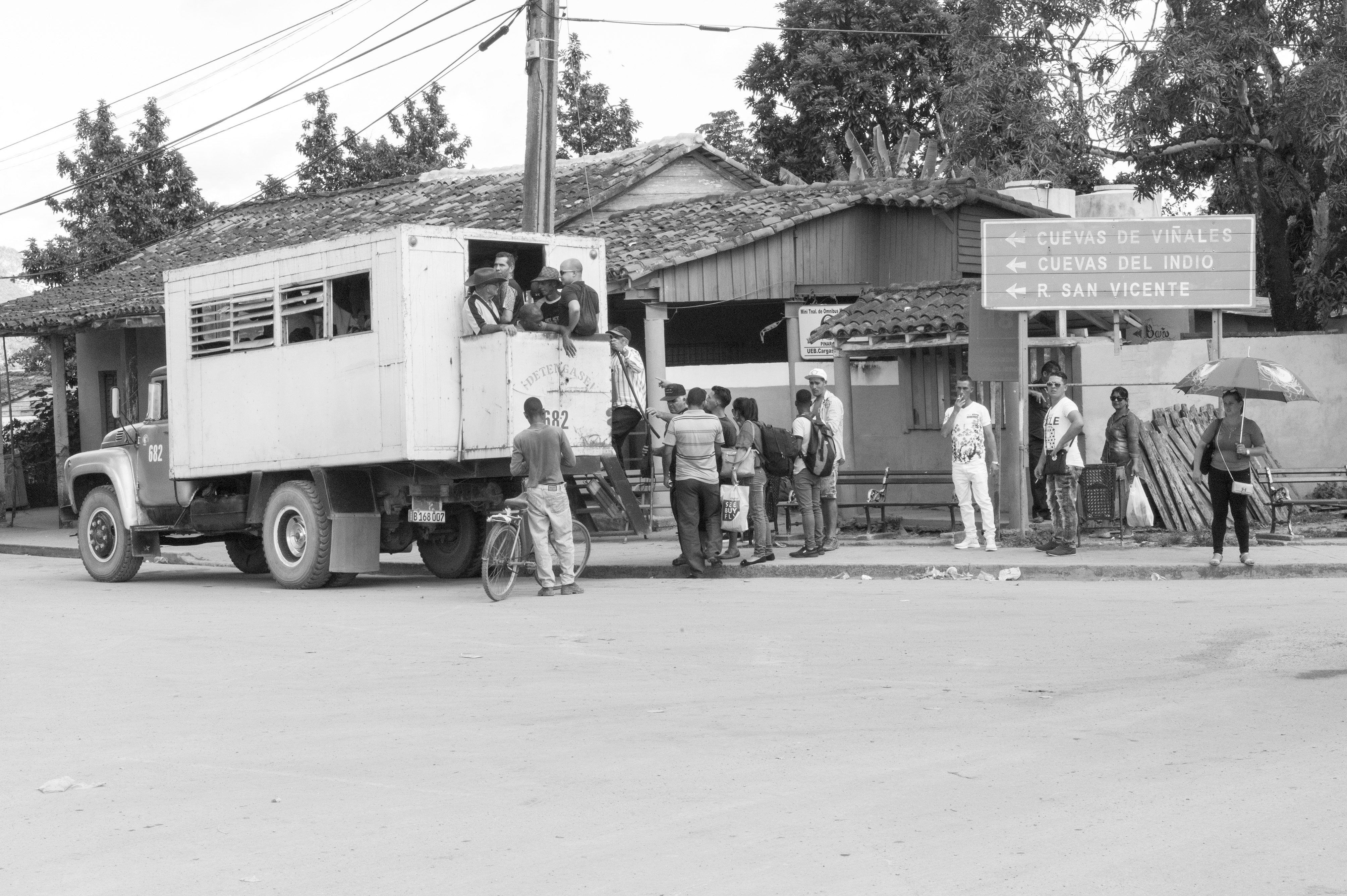

Back to reality on the streets and continuing to Trinidad (Cuba IV).

Back to reality on the streets and continuing to Trinidad (Cuba IV).

Leave a Reply